Compliance

Why a Type I product saves you money and ensures compliance over a Type M product

The only product of its type to carry the Kitemark. FastFlow products offer effective drainage systems, produced at the F&H foundry in the UK, catering for both surface and sub-surface drainage.

A type I can be laid in conjunction with standard parapet and surfacing materials. This gives a massive saving in both weight and cost of high strength concrete.

D400 Compliant at the point of purchase. No specific installation required to meet the loading

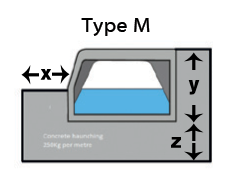

A typical type M unit requires approx 250 Kgs of high strength concrete haunching per metre to have any chance of complying with a D400 loading. It is the responsibility of the contractor to install exactly to the manufacturers detail to ensure compliance against standard, EN1433 states that;

"For type M drainage channels the manufacturer shall provide instructions for specific haunching and indicate dimensions x, y and z. The support needed on site shall be at least the support used for the loading test. A type M can be heavier."

A type M unit can be heavier per metre once encased in concrete; the cost of the concrete is high both in environmental and monetary terms. Type M units rely on using the correct installation detail to ensure compliance to standard. The sustainability of these types of units is questionable when all these factors are considered.

Saving you money whilst complying

To be sure that you are installing a product that has the lowest cost over its lifetime, is environmentally sustainable, meets the loading requirements under all conditions and will still be providing a trouble free drainage solution in fifty years, insist on a TYPE I Ductile Iron system.

Calculations based on 240mm wide x 100mm deep water channel, standard unit.