Installation

Straightforward to Install

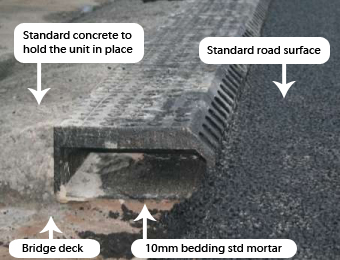

FastFlow bridge drainage units are straightforward to install, simply lay on standard bedding mortar and install. There is no requirement for the contractor to ensure the product is installed to specific criteria to maintain compliance. A Type I unit can be laid in conjunction with standard parapet and surfacing materials as per your design and build.

- Layout and arrange all units prior to installation and position rodding units and outlet units in the correct positions. Ensure any expansion joint assemblies are situated correctly.

- Install the expansion joint assembly first.

- Install to a line and level using 8mm - 10mm bedding mortar, ensuring the high point of the fall is maintained.

- Apply a 6mm - 8mm bead of sealant to one end of each unit directly before laying.

FastFlow is produced in a single piece for easy handling and installation; all units are supplied either as cast or with an eco friendly coating. The product is despatched from our premises direct to site or to the customer's specified location.

FastFlow is supplied packaged on robust pallets wrapped and banded for safe transportation and subsequent storage